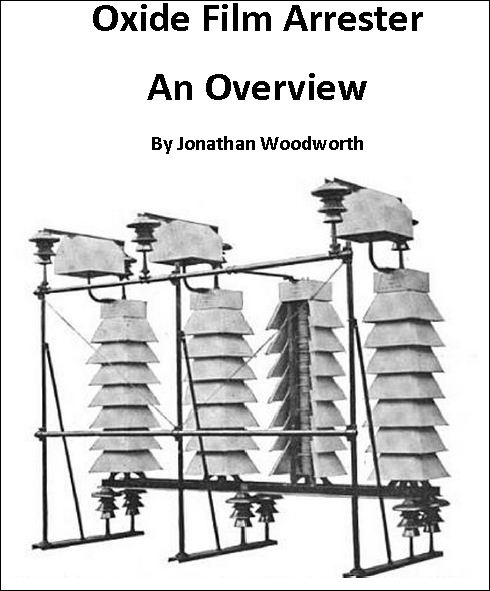

ArresterWorks Virtual Arrester Museum

Oxide Film Arrester

1920 Vintage

Still in Operation in 1969

Photo is part of The "Bill Kuhar Jr Collection"

Photo taken by William Kuhar Sr.

1969 at the Hauto Steam

Electric Station, Carbon County, Pennsylvania

Overview of Oxide Film Arresters and Hauto Power Plant

1924 Ad for Oxide Film Arrester

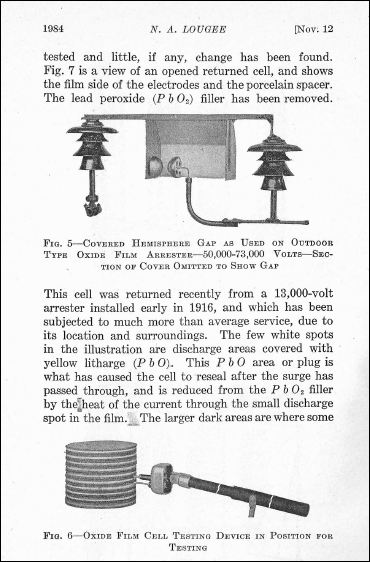

1920 AIEE Transaction Article on Oxide Film Arrester Testing

Anyone with more information about an

arrester like this is asked to contact

Jonathan Woodworth

at ArresterWorks

_____________________________________________________

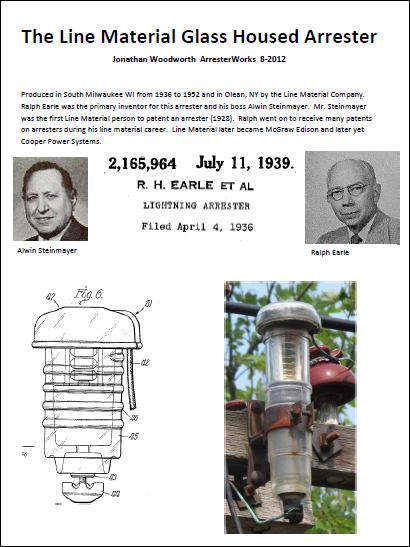

Line Material Glass Housed Arrester

In production from 1936 to 1958

This glass housed silicon carbide arrester pictured above was introduced in the late 1930s by the Line Material Company and produced from then until 1958. The factory where it was last produced was and still is located in Olean NY and is now part of Cooper Industries. This arrester had a significant influence on the factory location because the two most significant raw material suppliers were also in Western New York which in the 1950s was a more important consideration than it is today. The glass housing was produced by the Corning Glass Company then and still located in Corning NY, 80 miles to the east, and the silicon carbide material (black granular material in the bottom half of this unit ) was produced by the Carborumdum Company in Niagara Falls NY, 80 miles to the north. This arrester model design was modified in minor ways over its production life of 20 years, but the glass housing was a main theme the entire time.

To this authors knowledge, the Line Material Company was the only arrester manufacturer to use a glass housing. The arrester was designed in Milwaukee Wisconsin by Ralph Earl and Alwin G Steinmayer both of which were granted patent 2,165,964 for the design in 1936. In this photo it stands more than a half a century later still guarding the transformer that is most likely in the same age category. The glass housed arresters produced in the 40s and 50s can still be found around the world. It is estimated that more than a million units were put in service during the production years.

The rationale for using a glass housing was simply to make the internal parts visible so if the arrester was failed or damaged, it could be easily observed without testing. On the top half if this unit, the shiny brass electrodes that make up the gap assembly clearly indicate that this arrester is in pristine condition. Clearly (no pun intended) this unit is still in good working condition. The transformer was likely challenged by lightning numerous times during its life and it looks like its Sentry did its job since it is still powered and loaded.

Anyone with more information about an arrester like this is asked to contact Jonathan Woodworth

at ArresterWorks

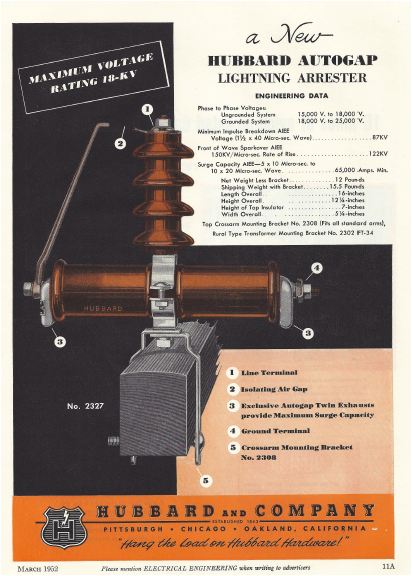

Hubbard AutoGap Arrester

Circa 1952

This Hubbard AutoGap Arrester has been protecting its transformer for

for perhaps 60 years. Hubbard an arrester manufacturer introduced this

arrester in 1952 and proclaimed better protection because it had

two vents for expulsion of the arc by-products. A 1952 Magazine Ad outlines the benefits of this new design. Hubbard was yet another Chicago company in the power system equipment business that has dissappeared.

This arrester was still in service as of May 2012 in the Upper Penesula

of the State of Michigan USA

Below is an arrester also from Hubbard, but of a slightly different design. This arrester is part of the Cooper Power Systems

Old Arrester Collection in Olean NY.

1952 Electrical Engineering Magazine ad about Hubbard Autogap Arrester

Anyone with more information about an arrester like this is asked to contact Jonathan Woodworth

at ArresterWorks

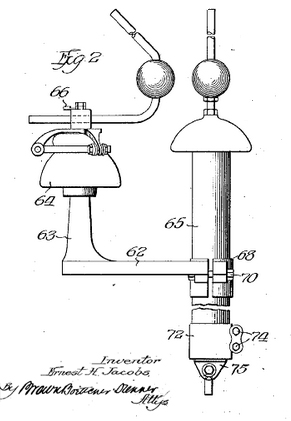

Horned Gap Arrester

Circa 1930

This Horned Gap Arrester represents the technology from

the early years of surge protection of power systems.

The exact year and manufacturer of this arrester is unknown

however it is similar to the design below that comes out of

a 1930 patent 1,755,324 by Ernest Jacobs of the Electric

Engineering Equipment Company of Chicago Ill.

This actual arrester is part of the Cooper Power Systems

Old Arrester Collection in Olean NY.

Anyone with more information about an arrester like this is asked to contact Jonathan Woodworth

at ArresterWorks

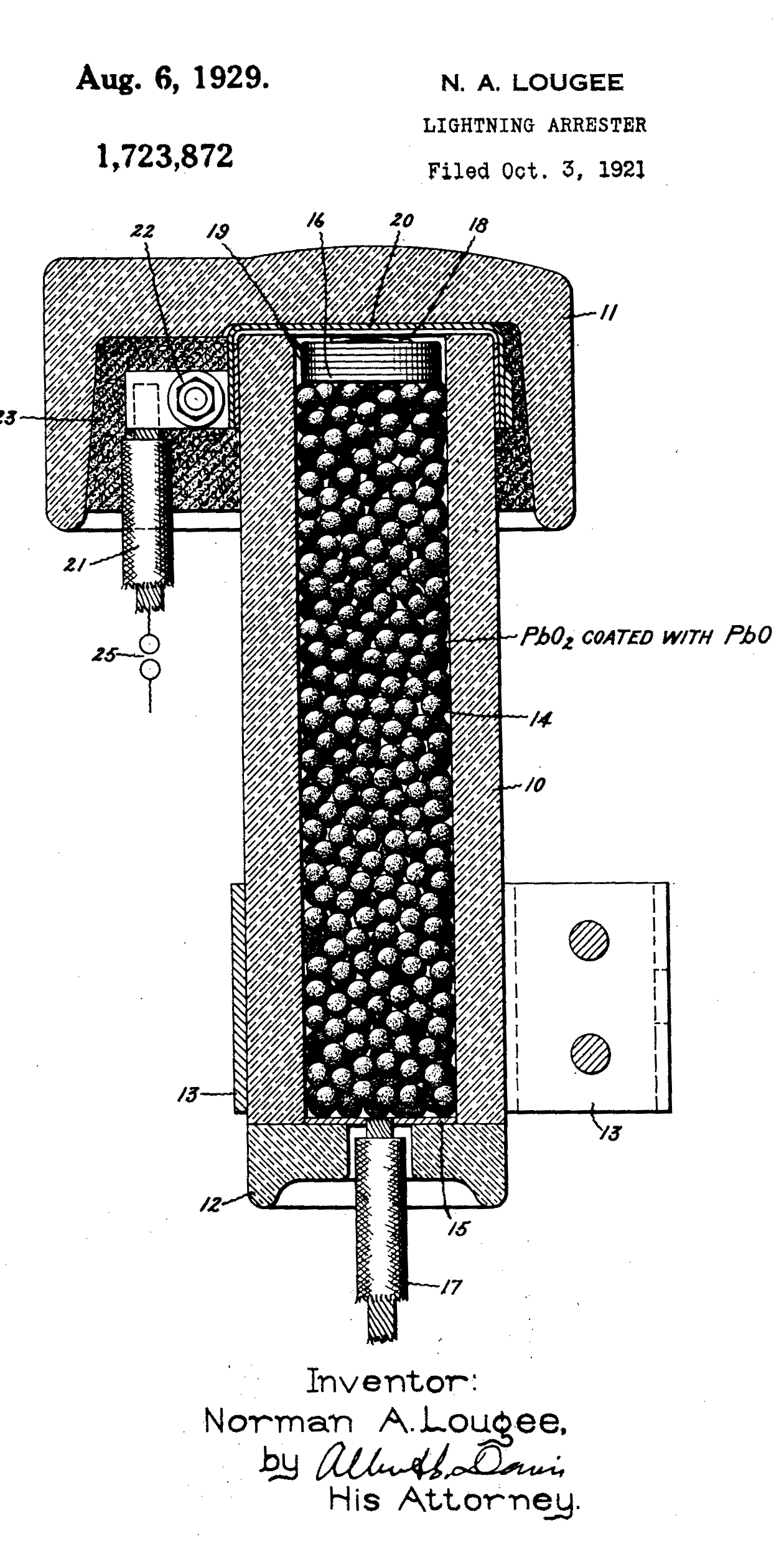

Pellet Type Arresters

650V Pellet Type Arrester

A GE Product Circa 1930

Pellet Type Oxide Film Arrester

Competing head to head with the first expulsion arrester was the new Pellet Type

Oxide Film Arrester. This new design was a product of arrester titan, GE. From

the patents and other literature, it is clear that GE had numerous engineers designing

arresters in this era. This new pellet type arrester had the excellent voltage

current characteristics of the Aluminum Cell arrester, but without a

liquid dielectric.

Patent 1,159,205

was granted to CF Frank for this design in 1915. In 1921 NA Lougee, also of GE applied for an improved

version of this arrester using peroxide lead pellets that was granted in 1929

(1,723,872). This design had an

additional advantage of lower cost and was better suited for line protection.

However, there were still lingering issues with this type of arrester.

It appeared to have a limited lifetime due to damage to the oxide film during

each surge. This damage was not repairable as in the liquid oxide film arrester.

Clearly more work was needed in the industry.

In the late 1930's the Silicon Carbide Type Arrester Technology obsoleted the lead oxide technology, but the use of

pellets continued on.

Fig: 1 1915 CF Frank Patent

Fig 2 1929 Norman Lougee Patent that resembles

the exhibited Pellet Type Arrester

The pellet arrester collection is from the ArresterWorks Arrester Collection